Exploitable Results

Explore the results that the project has delivered.

Hybrid Digital Twin for metal Additive Manufacturing

A cross-partner technical capability package delivering hybrid digital twin know-how—from testbed instrumentation and big-data pipelines to physics-based ROMs and AI defect detection—validated on metal 3D printers, using Laser-based Powder Bed Fusion (LPBF) process.

-

Scrap is detected too late in the LPBF/AM production chain, wasting machine time and lead time. With 30–70% of component manufacturing costs in post-processing and NDT, absent in-situ quality control cost overruns and delays.

-

Improved defect prediction driving Additive Manufacturing (AM) process control

Reduced waste and AM component rework

Foundation for closed-loop control and broader replication

Speed-up the calibration trials and the overal time to prepare Build Jobs using advanced simulation tools that predict deformation/residual-stress of the printed part

-

Metal AM (LPBF): In-situ monitoring, predictive defect detection, parameter optimisation, residual-stress/deformation prediction via ROMs.

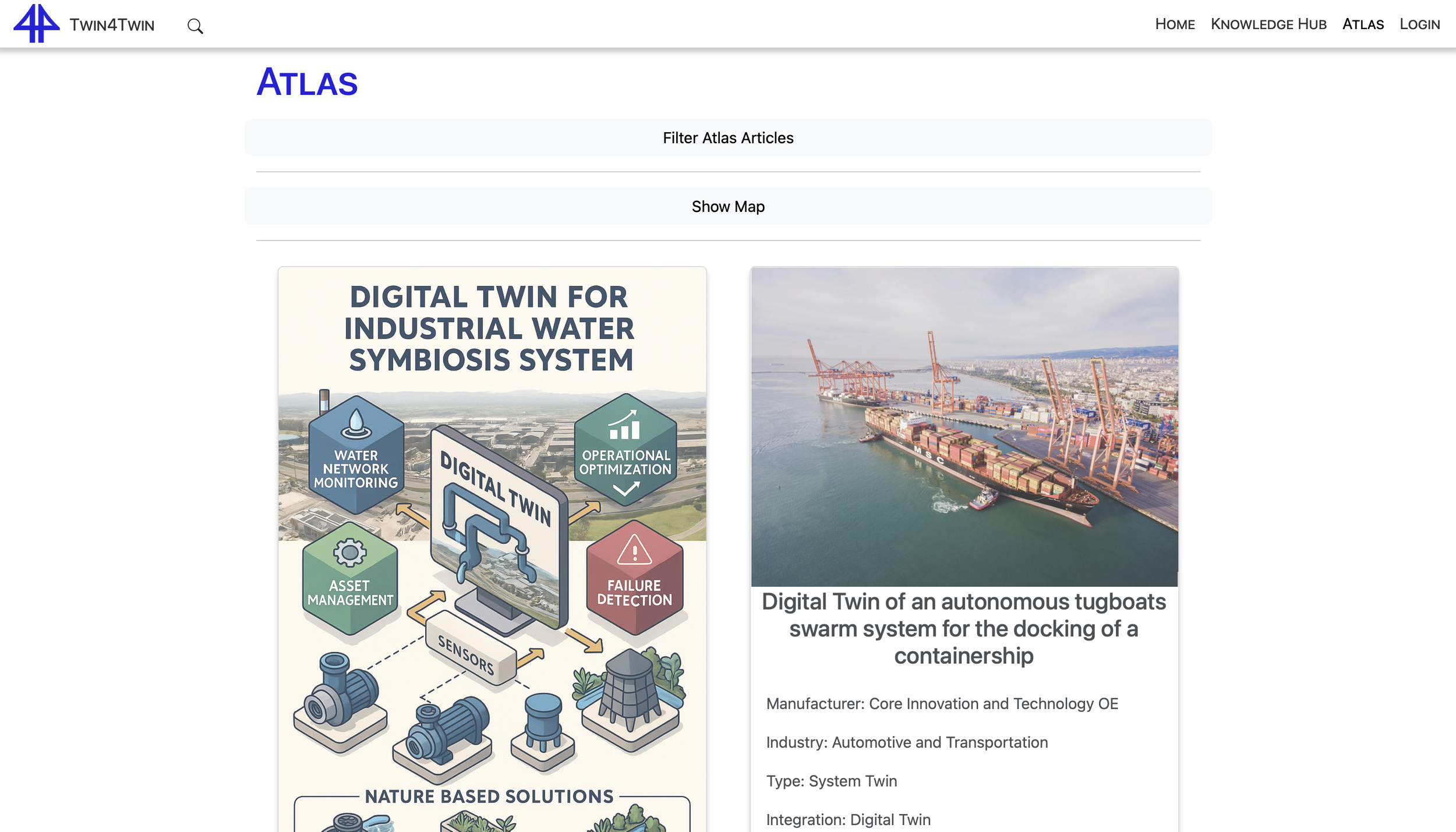

Digital Twins Best Practice Atlas

An interactive, web-based atlas that curates and visualises industrial Digital Twin applications across Europe, distilling transferable best practices, context, and implementation insights. Built with partners led by SSF, it enables discovery, comparison, and replication of proven digital-twin approaches.

-

Digital-twin know-how is scattered across projects, labs, and vendors, making it hard to find examples, benchmark outcomes, and replicate success. The Atlas centralises cases and practices, reducing fragmentation.

-

Faster scouting and replication of DTs

Promote a common DT terminology

Reduce barriers related to DT adoption

Evidence-based planning for Greek Smart Factory (GSF) and partners

Benchmarking visibility.

-

Digital Twin developers

Digital Twin research community

Digital Innovation Hubs

Smart Factories

Manufacturing Industry

CORE Innovation Days

A yearly Industry-4.0 conference and exhibition in Greece and Eastern Europe, organised by CORE, showcasing Industry 4.0 best practices, business cases and demonstrators. It is a catalysing event for networking, partnerships and project formation.

-

Greece’s Industry-4.0 ecosystem is fragmented, with limited digital skills and few fora linking academia, industry and policy. CORE Innovation Days addresses this challenge by bridging several actors from the Industry 4.0 landscape and mobilising collaborations towards the development of new technologies that solve real industrial needs.

-

Raises CORE’s scientific profile

Accelerates Digital Twin adoption

Sparks partnerships and pilots

Mobilises investments

Strengthens stakeholder engagement in the Greek Smart Factory

-

Greek manufacturing sector

Eastern Europe manufacturing sector

European Industry 4.0 ecosystem.

Business model for Greek Smart Factory

A practical business model and implementation plan for establishing the Greek Smart Factory, co-developed by CORE with expert feedback from SSF. It defines value proposition, membership and revenue streams, governance, infrastructure, pilot demonstrators, and a five-year roadmap for launch, growth, and sustainable operation.

-

Greek manufacturers lack a financially viable model to access test-and-demo infrastructure and services akin to the Greek Smart Factory. Fragmented stakeholders, unclear value propositions, and lack of funding routes delay the wide adoption of Industry 4.0 technologies.

-

Clear revenue and membership design

De-risked launch of the Greek Smart Factory

Faster adoption

Stronger academia-industry ties

Replicable national roadmap

-

Smart Factories ecosystem

Digital Innovation Hubs

CORE Proposal-to-Project serious game

An interactive training game that simulates the end-to-end journey from idea generation to high-quality Horizon Europe proposal development. It guides proposal development teams step-by-step through roles, workplans, budgets, and risks, supporting grant proposal writing and delivery.

-

Research teams struggle to convert ideas into fundable workplans; Public information about proposal-writing is scarce and practical training is not widely avaialble. The serious game standardises skills development, de-risks submissions, and improves pathway-to-funding.

-

Hands-on gamified training

Proposal step guidance

Improves access to funding

Reusablebeyond Horizon Europe (e.g., private R&I projects)

-

European research and technology organisations

Corporate R&D teams

innovative manufacturers that want to explore cutting-edge technologies

Proposal writing workshop

Annual hands-on workshop that trains CORE’s partners to turn ideas into fundable Horizon Europe proposals through interactive concept development that includes scope, roles, workplans, budgets and risks.

-

Proposal-writing know-how is siloed; research teams lack structured, practical training and time to transform ideas into competitive concepts. The workshop standardises skills, aligns partners, and accelerates high-quality grant-funding proposals.

-

Hands-on upskilling

Faster concept maturation

Higher funding success—three approvals after Workshop-1—

Scalable training targeting 80 participants across partners

-

European research and technology organisations

Corporate R&D teams

Knowledge Repository powered by Agentic AI

The result is an agentic-AI powered knowledge repository that centralises CORE IC’s research and innovation knowledge into a searchable, conversational platform. It orchestrates multi-agent workflows, document ingestion and response synthesis to support scientific writing, project management and strategic decision-making across EU-funded projects.

-

Today, Research and Innovation knowledge is fragmented across documents, emails and calendar events, making it hard to find, reuse and govern. Our knowledge repository not only organizes internal documents related to technical, financial, and legal management but also facilitates the retrieval of online sources for fact-checking and enhancement necessary for proposal and scientific text generation.

-

Increases efficiency in proposal writing and project management

Preserves institutional knowledge

Accelerates personnel onboarding

Improves decision making through consolidated access to CORE’s Research and Innovation knowledge.

-

Research & innovation project management

Proposal writing

Knowledge management

Personnel onboarding and role transitions.