Twin4Twin celebrates the successful completion of the 2nd CORE Innovation Days!

The Twin4Twin project is pleased to announce the successful completion of the second CORE Innovation Days, a key milestone in the project’s journey. Organised by CORE Innovation Centre (CORE IC), the event took place on 10–11 December 2025 in Athens, Greece, hosted at the Benaki Museum and the CORE IC premises in Athens, Greece.

The event brought together key stakeholders to showcase Industry 4.0 technologies and innovations, and to connect leading voices from Greek industry, international academia, policy-making, and the innovation ecosystem. Participants explored pressing industrial challenges and gained first-hand insights into technology-driven solutions and real-world industrial case studies.

CORE Innovation Days is an international event designed to inspire collaboration and strengthen partnerships across Greece’s research and innovation landscape. The programme highlighted emerging developments in Industry 4.0 and promoted strategic dialogue on the future of manufacturing and digital transformation.

The first day featured a conference attended by 205 participants, while the second day hosted an invitation-only workshop focused on proposal writing and consortium building for upcoming innovation calls.

Day 1: Conference Highlights

Opening Remarks

The conference opened with welcome addresses by Stefanos Kokkorikos and Nikos Kyriakoulis, Founders of CORE IC, followed by greetings from Stavros Kalafatis, Deputy Minister of Development and Investments at the Hellenic Ministry of Development and Investments.

As Twin4Twin Project Coordinator, Stefanos Kokkorikos then presented the project’s progress and key results, emphasising the importance of transforming purpose into impact.

Session A. Technology and Innovation for Industry: Adoption, Readiness, Infrastructure, and Opportunities

Moderated by Dr. Nikos Kyriakoulis (CORE IC), this session examined the current state of industrial transformation, highlighting key trends, challenges, and opportunities. Speakers explored how research and innovation initiatives, combined with targeted funding instruments, can accelerate technology adoption and deliver tangible value.

Maggie Athanassiadi (SEV – Hellenic Federation of Enterprises) discussed persistent industrial challenges in Greece, focusing on barriers to technology adoption and pathways to accelerate industrial competitiveness.

Raimund Klein (INCIT) examined industrial AI readiness, addressing the “90% problem” and the gap between AI experimentation and large-scale industrial deployment.

Dr. Denia Kanellopoulou (NCSR “Demokritos”) presented Pharos, Greece’s national initiative aimed at accelerating AI adoption and strengthening the country’s role in Southeastern Europe’s AI ecosystem.

Session B. Industrial Challenges

Moderated by Nikos Frangakis (CORE IC), this session focused on challenges across the manufacturing, process, and mining sectors. Discussions addressed interoperability gaps, collaboration barriers, and the accelerating pace of the digital and green transitions.

Dr. Milan Kumar (Independent Expert) shared insights into the practical realities of scaling AI solutions in complex, large-scale industrial environments.

Yannis Mamekas (Cosmos Aluminium) reflected on the company’s industrial transformation journey and the emerging challenges shaping its next growth phase.

Mark Rachovides (Euromines) outlined the future of mining in Europe, highlighting sustainability, innovation, and policy-driven transformation.

Panel Discussion: The Industrial Challenges from the Tech Providers' Perspective

The session concluded with a panel discussion examining industrial challenges from the technology providers’ perspective. Panelists shared insights into key pain points faced by technology providers, including deployment obstacles, interoperability gaps, collaboration barriers, and their views on navigating the Digital and Green Transitions.

The discussion, moderated by Nikos Frangakis, featured experts Xanthi Sousoni (LIFTCO LP), Christos Athanasiadis (Robovision), Foivos Psarommatis (Zerofect), Fernando Ubis (Visual Components), and Tomasz Barszcz (amc Technology Group).

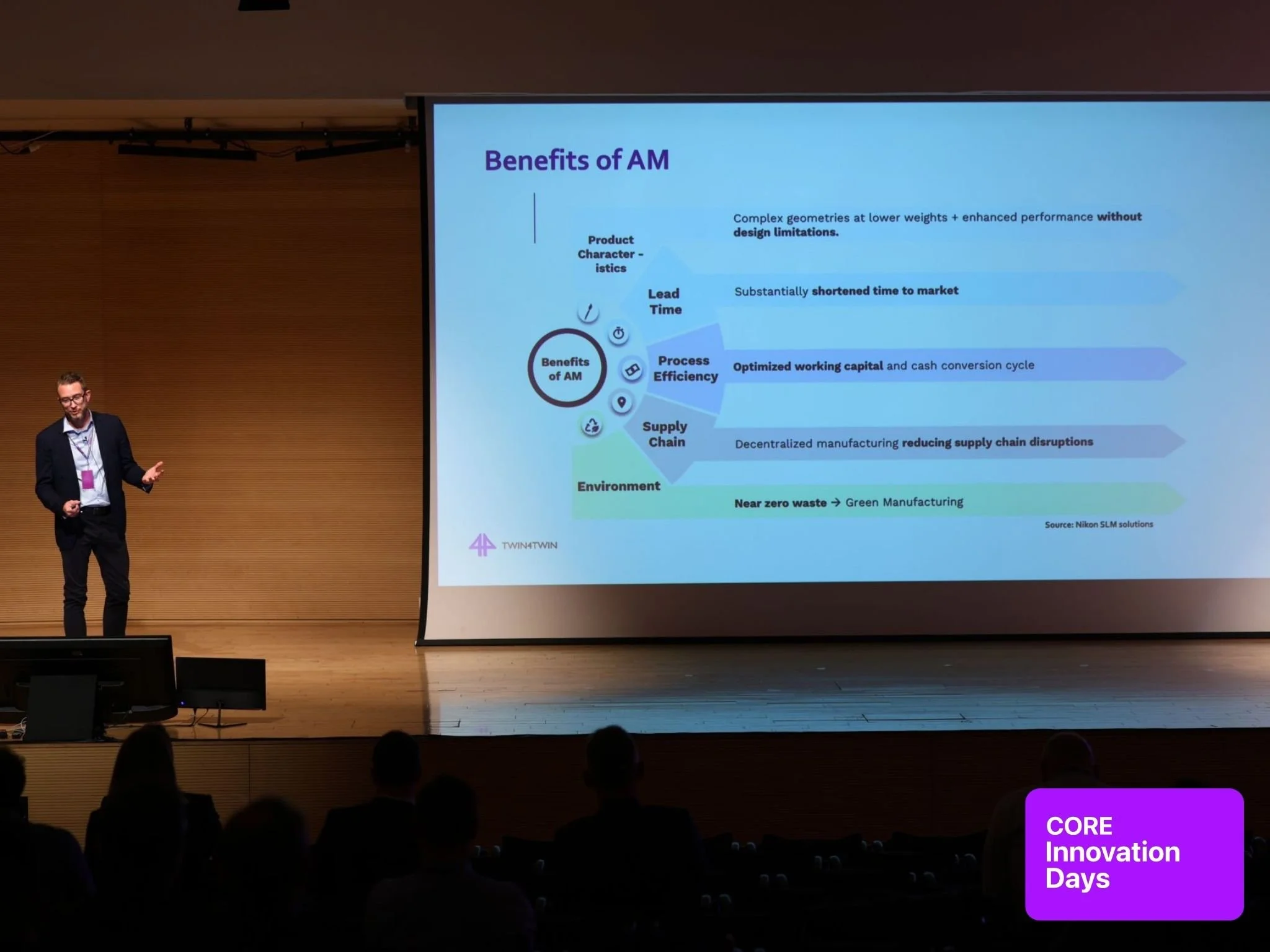

Session C. Technology Solutions

Moderated by Stefanos Kokkorikos (CORE IC), this session brought Industry 4.0 concepts to life through practical demonstrations, expert insights, and real-world examples from leading European innovation projects.

The session opened with an interactive stand-up panel by the CORE Innovation Group titled “Agentic AI in Action”, focusing on the development, deployment, and human-centric aspects of agentic AI. The discussion featured Dr. Apostolos Chondronasios, Christina Vlasi (CORE IC), and Meriem Jerbi (BORG Automotive), and was presented & moderated by Dr. Nikos Kyriakoulis (CORE IC).

Santiago Grandal Montero (AIMEN) explored how generative AI can enable smarter, more sustainable decision-making across industrial operations.

Dr. Giannis Karaseitanidis (ICCS) presented key Operator 5.0 enablers, focusing on human-centric technologies for collaborative industrial sorting lines.

Sébastien Lani (SIPBB) introduced the Twin4Twin digital twin approach for data-driven part quality decision-making in advanced manufacturing.

Prof. Paolo Pedrazzoli (TTS) demonstrated how virtual commissioning supports real-time control, risk reduction, and error prevention in manufacturing systems.

Panel Discussion: Back to the Future: Towards Augmented Manufacturing Workflows and Workforces

The session concluded with a panel discussion titled “Back to the Future: Towards Augmented Manufacturing Workflows and Workforces,” moderated by Dr. John Soldatos (Netcompany). The discussion explored how emerging technologies and systems—such as AI, agentic approaches, and data spaces—can effectively coexist and integrate with legacy industrial systems, addressing the practical challenges of interoperability. Panelists also emphasised the importance of human-centric approaches, highlighting the role of augmented workflows that support, rather than replace, human operators. Particular attention was given to workforce upskilling, continuous learning, and training, as critical enablers for the successful adoption of advanced digital technologies in manufacturing.

The panel featured expert contributions from Prof. Pedro Malo (University of Minho), Sergio Gusmeroli (MADE Competence Center & Politecnico di Milano), Dr. Nikos Kyriakoulis (CORE IC), and Prof. Dimitris Kyritsis (EPFL & University of Oslo).

Session D. Success Stories

Moderated by Dr. Nikos Makris (CORE IC), this session showcased success stories demonstrating how Industry 4.0 technologies are delivering measurable impact across European industries, from concept to large-scale deployment.

Dr. Dominik Rohrmus (LNI4.0 & Siemens) presented international manufacturing data ecosystems that enable trusted data sharing and accelerate AI adoption.

Argyris Patousias (Hellas Gold) showcased how private LTE campus networks are advancing digitalisation and operational efficiency in mining operations.

Dr. Jacopo Cassina (Syxis) shared the Machinery X journey, highlighting the transition from research-driven innovation to industrial application.

Panel Discussion: Industry 4.0 in the Process and Mining sectors - Success Stories

The session concluded with a panel discussion on “Industry 4.0 Success Stories in the Process and Mining Sectors,” highlighting real-world cases where automation and digital technologies delivered tangible performance improvements, such as increased plant uptime, higher OEE, reduced scrap, and improved energy efficiency.

Panelists also discussed common challenges in implementing Industry 4.0 projects—including system integration, workforce resistance, ROI uncertainty, cybersecurity, and skills gaps—and shared insights into the key enablers that supported successful deployment and organisational adoption.

Moderated by Dr. Nikos Makris, the panel featured Dr. Panagiota Tsarouchi (HALCOR), Marta Rabal (CIRCE), Irene Garcia Martinez (CELSA), and Vasilis Papaloukas (METLEN).

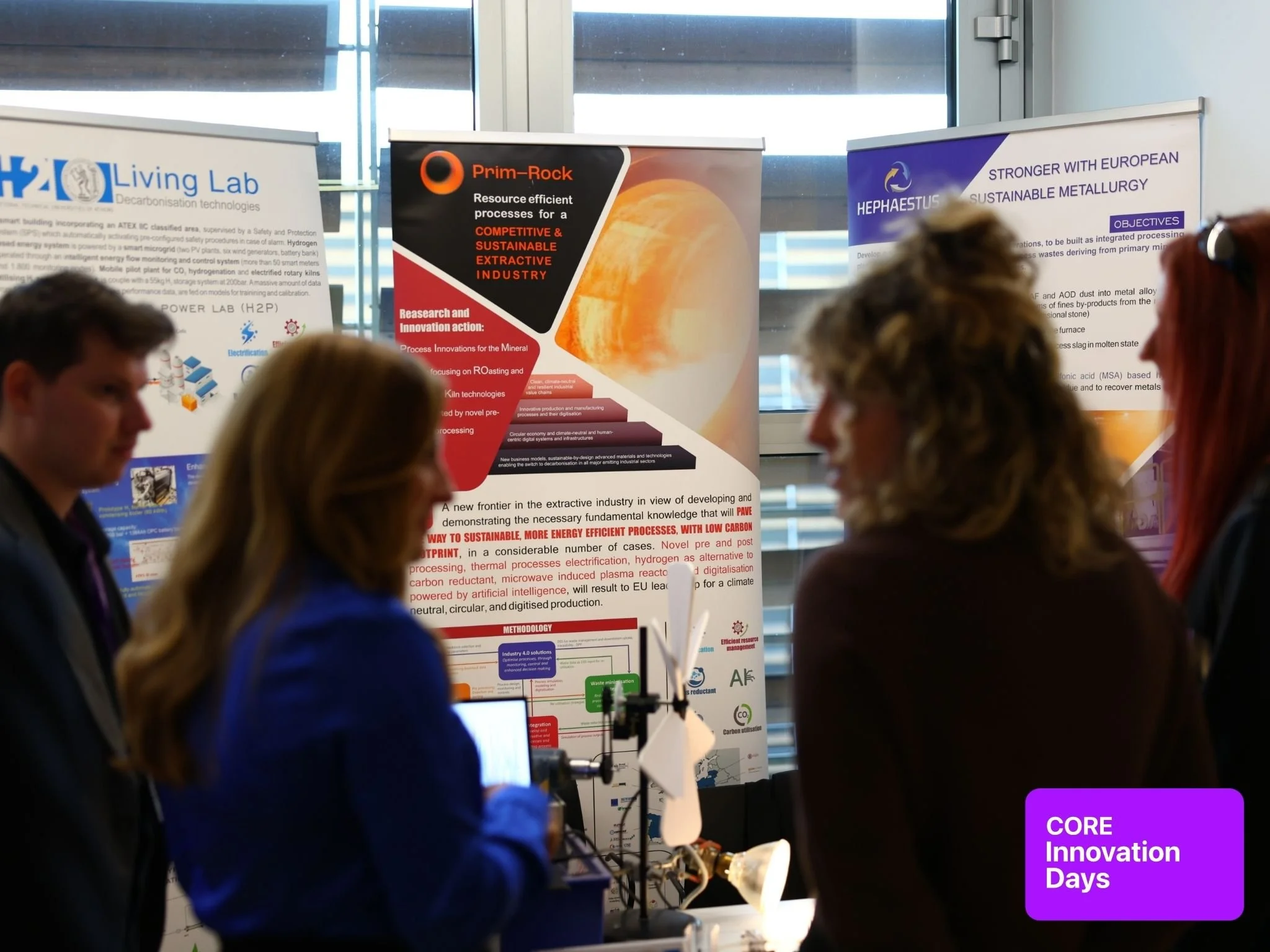

Parallel Session: Demonstration of Technologies and R&I Projects

Throughout the conference, a dedicated Demo Area hosted live demonstrations of advanced solutions developed within European research and innovation initiatives. Highlights included:

SCCH’s Knowledge-Graph Tool for Process Analysis

NTUA’s hydrogen-based energy systems via its Living Lab

Advanced recycling solutions from NTUA-RNano-Lab (PRecycling project)

Avanti, an AI-driven HR platform by R2M

CORE IC’s LPBF Digital Twin for Metal Additive Manufacturing

CORE IC’s Reman Guidance System (RGS) for AI-based remanufacturing decision support

COREbeat, an end-to-end predictive maintenance platform integrating IoT, edge computing, and AI

A dedicated booth for Greek Smart Factory gathered valuable feedback from industry stakeholders through an interactive survey.

In parallel, numerous European R&I projects were showcased, including Twin4Twin, ELEXIA, M4estro, Modul4r, Dacapo, MASTERMINE, OPTIMINER, REUMAN, PRIM-ROCK, StreamSTEP, CARDIMED, NURISH, TRINEFLEX, PRecycling, BioPackMan, and Eurocomp.

Twin4Twin partners contributions

Twin4Twin partners played a prominent role throughout the event. Sébastien Lani (SIPBB) contributed as a keynote speaker, while Dr. Mario Pichler and Dr. Georgios Chasparis (SCCH) actively participated in the conference and hosted an exhibition booth presenting results from the Twin4Twin project.

CORE IC showcased multiple exhibition booths, including the Greek Smart Factory initiative and the LPBF Digital Twin for Metal Additive Manufacturing—a real-time, AI-enhanced solution that monitors, analyses, and detects defects in Laser Powder Bed Fusion processes using sensor data, simulations, and in-situ imaging.

All partners also participated in the closed, invitation-only Twin4Twin Proposal Writing Workshop on Day 2.

Day 2: Twin4Twin Proposal Writing Workshop

The second day featured a closed workshop at the CORE IC headquarters, bringing together 56 selected participants. Structured around 16 thematic areas and 31 parallel workshops, the hands-on sessions supported participants in exploring upcoming funding opportunities and building strong consortia for future research and innovation calls. The workshop highlighted the importance of collaboration in advancing the Twin4Twin vision.

An engaging and Memorable Experience

Across both days, CORE IC ensured a welcoming and high-quality experience, supported by professional demonstrations, printed materials, and digital assets. Discussions highlighted advances in Industry 4.0, emerging funding opportunities, and the strategic role of Twin4Twin in strengthening Europe’s industrial innovation ecosystem.

Building on the success of these events, CORE Innovation Days has now become an annual gathering, bringing together key stakeholders to showcase cutting-edge Industry 4.0 technologies and provide industry with valuable insights into their practical applications, transformative potential, and long-term strategic deployment—well beyond the lifetime of the project.